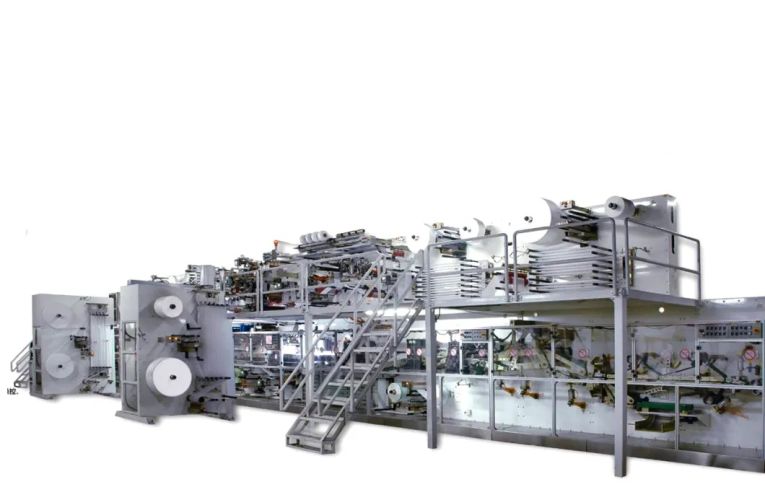

Baby Diaper Making Machine

Fully Automatic Baby Diaper Making Machine (Capacity: 600 pcs/min)

Baby diaper production line includes main machine, glue applicators, packing system and other accessory equipment including air compressor, vision detection system and metal detection machine etc. Baby diaper machine can produce 4-6 sizes diapers according to the order. They can customize the T-type, I -type and Pull-on Type baby diapers according to the customers’ request.

This machine will need the following materials :

Fluff pulp, non-woven, tissue, film, SAP, glue, ADL, elastic ribbon, colour tape, throw tape.

|

T-Type |

Pull-On Type |

I Type |

Parameters

| 1.Product Structure | 1)Thick type diaper: Leak-guard non woven, Cuff spandex , top sheet hydrophilic non woven, ADL, top tissue paper(or non woven), cotton core+SAP,down tissue(or non woven), PE film backsheet,leak-guard elastic ribbon, inner non woven on waistband,outer non woven on waistband, waistband ribbon,leg ribbon, colorful tissue |

| 2)Medium and thin type diaper: Leak-guard non woven, Stereoscopic protection spandex , top sheet hydrophilic non woven, ADL, top tissue paper(or non woven), cotton core+SAP,down tissue(or non woven), PE film backsheet,leak-guard elastic ribbon, inner non woven on waistband,outer non woven on waistband, waistband ribbon,leg ribbon, colorful tissue | |

| 3)Ultra thin type diaper: Leak-guard non woven, Stereoscopic protection spandex , top sheet hydrophilic non woven, ADL, top tissue paper(or non woven), cotton core+SAP,down tissue(or non woven), PE film backsheet,leak-guard elastic ribbon, inner non woven on waistband,outer non woven on waistband, waistband ribbon,leg ribbon, colorful tissue | |

| 2.Product specification | M、L、XL、XXL(mm) |

| 1)M:total length:470 waistband width:395 | |

| Diaper pad length*width:425*180 cotton core length*width:385*120 | |

| 2)L:total length:490 waistband width:395 | |

| Diaper pad length*width:425*180 cotton core length*width:385*120 | |

| 3)XL:total length:510 waistband width:415 | |

| 4)XXL:total length:540 waistband width:415 | |

| Diaper pad length*width:460*180 cotton core length*width:420*120 | |

| Based on production picture | |

| 3. Design speed | 700pcs/min |

| 4.Stable production speed | 500-550pcs/min (M) |

| 5.Center distance of production line | Referring to distance between the center line of product material and main frame plate,250mm |

| 6. Distribution of raw materials | The surface layer of the compound surface of non-woven fabric is the core body. |

| 7.Product weight tolerance | ±5% |

| 8. Rate of finished product | ≥97%(not including the defective products caused by glue applicators, feeding of raw materials and joints of raw materials |

| 9. Efficiency range | ≥85% |

| 10. Power | 320KW |

| 11. Weight | 76.5T |

| 12. Electric supply | 380V±5%、50HZ |

| 13. Dimension | 26.6m ×2.3m×3.7m (L×W×M,Include crusher) |

| 14. Air pressure | 0.6-0.8Mpa(Buyer need to prepare for air source) |

| 15.Working direction of machine | to be decided by buyer |

| 16. Color | White (It depends on customer’s requirement) |

| 17. Glue sprayer | Use encoder, use independent servo drive |

Spare parts Brands

| Name of parts | Brand |

| PLC | Siemens |

| Touch Screen | Siemens |

| Servo control drive: 35sets | Siemens |

| Stain detection | China |

| Auto web controller:4 sets | BST |

| Bearing use imported bearing | NSK/NTN/ |

| Timing belt | Gates/Tiger |

| Flat belt | Nitta/Tiger |

| Low-voltage electrical apparatus | SCHNEIDER |

| Air cylinder/pressure regulating valve/electromagnetic valve | Airtac |

Features

- Fully servo motor driving system for precise transmission.

- the 3D cotton core formed in drum type.

- Constant tension control rolling drive.

- Automatic non-stop roll replacing.

- Pneumatic rolling shaft for easy feeding materials.

- Built-in automatic inspecting and eliminating defects.

- 3D side-leasing-proof wall and elastic waistline composite mechanism.

- Built-in auto-editing and correcting system.

- Touch screen control panel with a graphic man-machine interface.

- S-shape cut of left and right waist pastes.

- Online elastic waistline lamination.

- Online back sheet lamination.

- Positioned cutting of Back sheet and front waistline paste.

- Fully servo motor driving stacker and automatic packaging machines.

- Designed and manufactured as CE regulations and standards.

Technical Parameters

- Power Source: Three Phase: 380 V 50 Hz

- Installation Power: 320 KW(excluding glue applicators, air compressor, the final power shall be confirmed after completion)

- Product Sizes Medium and large sizes (only changing crotch size instead of changing waist size)

- Production Speed: 350 PCS/min (Medium)

- Qualification Rate≥ 96%(excluding glue applicators, wastes caused by splicing raw materials)

- Overall Size(L× W× H): 38m× 12m× 4.5m(for reference)

- Machine Process Direction (raw material TO products)right to left(facing machine)

Product Structure

- Core layer structure: Big cotton core adopts alien continuous stripping to shape and small cotton core adopts direct buckle the forming. Big cotton core and small cotton core are pressed solid after wrapping by tissues.

- Acquisition layer slitting adopts scraping. (Scraping length is controlled by servo motors. )

- Top sheets are composed of side nonwovens with elastic and middle materials, compressed by embossing units.

- Nonwoven sectioning units adopts motor sectioning mode.

- The tightness of elastic is adjusted by double roller linear velocity controlled by frequency conversion.

- Roll material and tube material are compatible with elastic feeding.

- Cotton core cutting and final product cutting adopt side blade scraping.

- Colour calibration of the former icon straight cut adding unit.

- Waist combination adopts heat seal.

- Detailed shape, structure, sizes of products are confirmed according to the finalized products by both parties.

I want to know the price range of a diaper making machine

I want to know the price range of a diaper making machine.