Disposable Medical Latex / Nitrile Hand Gloves Production Line

Natural latex/Nitrile glove production line using a continuous production and direct immersion mode, film uniformity, can be used for medical surgical gloves, examination gloves, medical powder, no powder-coated gloves. Automatic ejection, high yield, a product without hanging points.

- Adopt the most advanced gloves production technology and production process layout, product qualification rate is more than 98%, protein content is lower than 120 micrograms per gram.

2.TPU Coating technology. - Imported surfactant solidifier, the finished membrane is uniform, no powder mold release.

4.The introduction of foreign advanced transmission main chain structure, chain little resistance during operation, Production of high speed, stable operation. - The main motor drag solves the drag, difficult to synchronize, fault point, difficult maintenance, and other issues.

- Adopt vertical hot air circulation drying oven, compared with other forms of hot air circulation, save energy consumption by almost 20%.

7.Used for cleaning mold splitter six roller long hair scrub mould technology.

8.Mold directional, machine printing technology. - A variety of specifications of production, on the same edge automatic adjustment, the PU edge roller, long service life.

10.Can design according to the needs of customers of different length, height, cost models.

Production Process

Latex Gloves Production line technical parameters

| S.No | Size (M) | Capacity | Heat | Power | Mold |

| (pcs/hr) | (kcal/hr) | (kw/hr) | (pcs) | ||

| 1 | 55M | 3400 | 95 | 15 | 1800 |

| 2 | 65M | 4000 | 90 | 18 | 2200 |

| 3 | 75M | 4800 | 85 | 20 | 2500 |

| 4 | 85M | 5500 | 80 | 25 | 2900 |

| 5 | 100M | 6500 | 70 | 30 | 3400 |

| 6 | 110M | 7200 | 60 | 30 | 3800 |

| 7 | 120M | 8000 | 55 | 30 | 4200 |

Nitrile Gloves Production line technical parameters

| S.No | Size(M) | Capacity | Heat | Power | Mould |

| (pcs/hr) | (kcal/hr) | (kw/hr) | (pcs) | ||

| 1 | 55M | 3400 | 900 | 15 | 1800 |

| 2 | 85M | 5400 | 750 | 15 | 2900 |

| 3 | 100M | 6500 | 650 | 15 | 3400 |

| 4 | 120M | 7800 | 550 | 15 | 4200 |

| Heating Method | Natural gas, steam, heat conduction oil | ||||

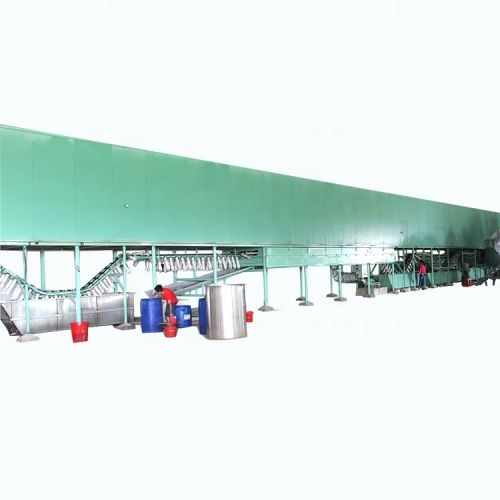

Machine Photos

Corollary Equipments

What’s up, I am an avid reader of your website! I really agree with this as I am currently employed as a medical scribe for a BPO provider.

Respectfully, sirs,

I hope this finds well.

Eng. Ahmad Bahasan from Saudi Arabia is here. I’m writing to enquire about the glove manufacturing line machines (Latex, Nitrile, Vinyl). As a matter of fact, I’d want to learn more about the maximum capacity of manufacturing, as our standard is 10,000/hr. for the aforementioned items. In addition, I’d like to ask for your assistance in sharing the machine dimensions and the installation requirements. So, in order for us to share the quotation, I’d like it if you could organize a meeting with the Jorpimcon marketing team to go over the details and specifications of your equipment in further detail.

1. What are the major material resources for the manufacturing line?

2- Size of gloves required: (Small – Medium – Large – XL)

3- Dimensions of the machine, as well as pre-installation needs and information

3- The number of workers per production line.

4- Are there any solutions for a fully automated assembly line in the final phase?

Please let me know if any other details are required.

Regards,

Ahmed Bahasan.